What If Ben Franklin Invented Modular Construction?

Ben Franklin was the oldest of the founding fathers. Most people don’t realize that he was more than twice the age of Thomas Jefferson when they signed the Declaration of Independence (33 vs. 70)! Ben had already had a rather full life. He was a tinkerer, an inventor, an observer, a writer, and a philosopher. Along with many other things, he invented swim fins (1717), the Franklin Stove (1741), the lightning rod (1750), and bifocals (1784). All of these things we use today are still in mass production. Where would modular construction be if Ben had invented it in the 1700s!?

We Had It… But We Lost It…

Modular construction consists of volumetric modules, which are typically fabricated offsite. They are then delivered to the final site and installed or assembled. The term module here doesn’t refer to a singular wall, floor section, or even doors or windows. It refers to an enclosed dwelling space. Throughout the history of home building in the U.S., there are many examples of building homes in factories. But without Ben Franklin’s help, the onsite method of building a home has had a long time to grow and establish itself; it has become the ingrained way to build. The entire support industry, tooling, materials, and now software supports building onsite. However, we can’t continue to do it that way. As an industry, we know building onsite isn’t sustainable going forward. So today, large production home builders to small custom home builders are researching offsite construction.

Modular bungalows were available in the early 19th century. Henry Manning, a London carpenter, produced the Portable Cottage in 1837 for export to Australia. The California Gold Rush of 1848 saw imports of prefabricated houses from Britain, Sweden, and China arrive to house the 49ers. When there was a need for homes but labor wasn’t available, or locations were remote, modular construction has stepped in. Offsite modular construction has been available and used for almost 200 years. But, when labor becomes plentiful, and resources are cheap, the industry does what is easy for it. It builds homes onsite.

So, What is Offsite Construction?

The term offsite construction means that some or most of a home is built at a location that isn’t its permanent location. Many think that offsite or modular construction is new, but it’s not! In the 1800s, everything was built on the home site. This included windows and doors. Eventually, builders determined that windows and doors could be more efficiently and cost-effectively constructed indoors in a factory and then delivered to the site. This concept grew to include more and more components that were historically built onsite. In the 1830s, an English company started to use modular construction by building homes in England and shipping them to Australia.

After another 100 years, the modern roof truss industry was born in 1952. Trusses took a while to be adopted by builders that were used to building roof rafters onsite for every home. Old school builders didn’t understand them and believed the way they had always done it was the best way. However, they soon discovered that their high strength-to-weight ratios permitted longer open spans, which meant greater flexibility in floor plan layouts. They could also be designed in almost any shape or size. Roof trusses were built offsite, and their only restrictions were manufacturing capabilities, shipping limitations, and handling considerations.

The industry has almost entirely adopted roof trusses. However, there are still a number of builders that have resisted them and continue to build rafters onsite. Next came floor trusses. And for all of the same reasons. The most important takeaway here is that trusses can be built offsite that are engineered to be stronger, that are more cost-effective, and that can be installed onsite faster than rafters built the traditional way. The natural evolution of construction now leads us to the next leap forward.

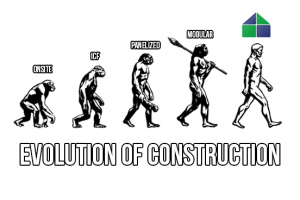

The Evolution of Home Construction

There are several offsite methods of construction. One that is used by many production builders is panelized construction. What this means is that the skeleton of a home, the home’s framing, is broken down into panels (i.e., pieces or components) that are built on jigs or automated machines. These panels typically include walls and floors that are pre-assembled offsite and then trucked to the home site. There, they are assembled, and then roof trusses are added. Instead of a home’s frame being built onsite, one stick at a time, the home is actually assembled by placing the prefabricated panels together. This can save several days in the process and lead to better quality. However, everything else still has to get done onsite. This means that the home is susceptible to many of the same issues that come with building onsite.

There are several offsite methods of construction. One that is used by many production builders is panelized construction. What this means is that the skeleton of a home, the home’s framing, is broken down into panels (i.e., pieces or components) that are built on jigs or automated machines. These panels typically include walls and floors that are pre-assembled offsite and then trucked to the home site. There, they are assembled, and then roof trusses are added. Instead of a home’s frame being built onsite, one stick at a time, the home is actually assembled by placing the prefabricated panels together. This can save several days in the process and lead to better quality. However, everything else still has to get done onsite. This means that the home is susceptible to many of the same issues that come with building onsite.

RELATED: 5 Simple Truths About Modular Off-Site Construction

Modular construction means more, if not most, of the pieces used to build a home are pre-assembled offsite. Sub-components and components are assembled into modules. These large modules are then shipped to a home site on carriers by large trucks and assembled in LEGO-like fashion on a foundation (that could also have been prefabricated offsite). What modular construction does is reduce or eliminate many of the risks in construction. These risks include Schedule Risks, Scope Creep/Change Orders, Weather Issues, and Skilled Labor Dependencies.

The Old Ways of Doing Construction Make it Riskier

While many still believe that the old way is the least risky way, that isn’t necessarily true any longer. The traditional approach just isn’t the best way to manage risk when building a custom home today. Subcontractors are busy and suffering from an extreme lack of skilled labor. When you add the unpredictability of weather to their already precarious position of waiting to see who actually shows up to work each morning at a job site, each morning becomes a roll of the dice.

That same issue trickles down to everyone in the construction chain. Did the truck driver show up on Monday morning to deliver the load of lumber needed for the framing crew to get started? Did the trim get delivered for the trim carpenters to get started? In today’s world, why is the home building industry the only industry that is stuck doing it the way it has been done for almost 200 years?

Do More With Modular!

While modular construction would have been cool way earlier in history if Ben Franklin had invented it in the 1700s, we are there today. A modular home is designed to provide America’s home buyers with a well-built, high-quality home. It can do this at a value that can only be provided by utilizing the efficiencies of indoor factory construction. Combine that with outstanding design flexibility and high energy efficiency, and you have a combination that far exceeds that of a home built using traditional outdoor construction.

Modular is the fully evolved form of a building system. It completes the maximum amount of work in a factory and delivers modules of a home plan to a home site where it is assembled in LEGO-like fashion. The inherent strength of this building system makes modular homes stronger and more resilient. Families that live in a modular home are safer. Homes arrive 65-85% complete. Ultimately, modular is the fully evolved form of home construction.

The post What If Ben Franklin Invented Modular Construction? appeared first on Impresa Modular.