How We Get Home Modules to Difficult Home Sites

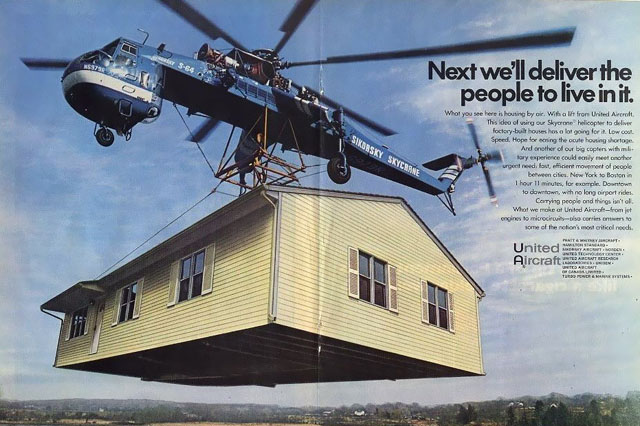

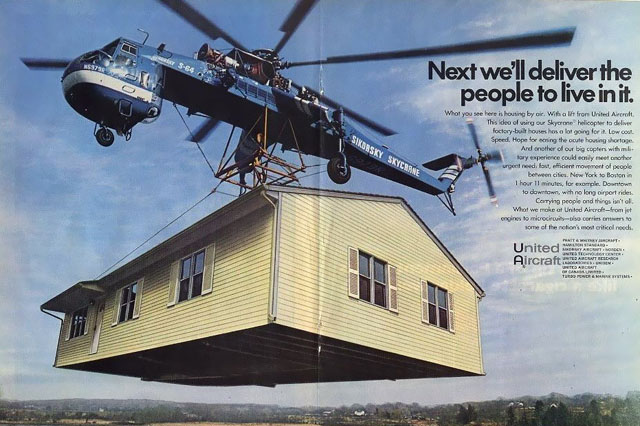

Many times we are asked how we got the large sections of a modular home to a home site. Did we use a helicopter? A helicopter isn’t the standard way to deliver modules of a home to a home site. The Sikorsky advertisement from the ’70s shows an S-64E lifting a home. Today’s modular homes are typically too heavy. In some cases, a single module could exceed the capacity of even today’s largest helicopters. But, we have other ways to get your home’s modules to some of the most difficult home sites. Here are some unique tools we use to deliver a home to virtually any location.

The Modular Advantage

As a proponent of modular construction, the opportunity to provide custom homes built in a factory just makes sense. The protection from the weather, the value that can be achieved, and the quality that can be delivered all add up to make modular construction the premier method for providing a custom home. But the reality is that you have to be able to deliver that home’s modules to a site and you have to be able to do it cost effectively. The industry has created highly specialized equipment to get modules practically anywhere.

A module is a large “box” or section of a modular home. Most modules come in widths of 12, 14, or 16 feet wide. In some regions of the country a home section can be up to 20 feet wide. A homes length can vary. Smaller homes have modules are that are 28 feet long and possibly smaller. Larger homes can have modules that extend to 76 feet long. Imagine driving a specialized semi-truck called a Toter that is pulling a module that is 16 feet wide and 76 feet long on a narrow road or on a city street. It happens every day and is done by expert drivers pulling the modular sections on specialized trailers called a carrier. The combination of a Toter truck, a carrier, and an expert driver makes what looks impossible, possible every day.

The Right Tool for the Job

Getting all of the modules of a home to a home site is the first step to erecting a modular home on a site. Needless to say, reputable modular home companies have gotten very good at getting modules to sites that many would think required a helicopter for delivery. There are other special tools and equipment that can get large modules to difficult sites. Excavation equipment is used to navigate steep hills, tight turns, and muddy sites. Other equipment such as Jades, Tugs, and Translifts have been developed just to get large modules to sites that otherwise would be inaccessible.

When it comes to getting a home’s modules to some sites, it is important to have the right tool. Here are some pictures and descriptions of the tools and pieces of equipment that can be used to get to very difficult sites. Notice that a helicopter doesn’t make the list…

Toter Truck – Modular homes are pulled to the home site with a special truck known as a toter truck. A toter truck has a hitch on the rear of the truck as compared to most large trucks where the trailer rides over the rear wheels of the truck. There are many version of this type of truck. When being pulled on the main highways toter trucks usually have tandem axles and large bodies making it ride smoothly for traveling the longer distances to home sites in a region. However, on side streets and rural roads their length can limit maneuvering ability. Smaller, single axle toters with specialized hitches that can move in multiple directions can make getting modules to a home site much easier.

Toter Truck – Modular homes are pulled to the home site with a special truck known as a toter truck. A toter truck has a hitch on the rear of the truck as compared to most large trucks where the trailer rides over the rear wheels of the truck. There are many version of this type of truck. When being pulled on the main highways toter trucks usually have tandem axles and large bodies making it ride smoothly for traveling the longer distances to home sites in a region. However, on side streets and rural roads their length can limit maneuvering ability. Smaller, single axle toters with specialized hitches that can move in multiple directions can make getting modules to a home site much easier.

House Cat or Tug – A house cat is basically a mini bulldozer that is remote controlled. An operator remotely controls the miniature unit that is actually very heavy but very nimble. It can make very sharp turns in very tight areas. Because of its weight and tracks, it is also very good at getting modular sections up steep hills and mountains. While it may move slowly, speed isn’t the consideration when it comes to getting a houses modules to the site location.

House Cat or Tug – A house cat is basically a mini bulldozer that is remote controlled. An operator remotely controls the miniature unit that is actually very heavy but very nimble. It can make very sharp turns in very tight areas. Because of its weight and tracks, it is also very good at getting modular sections up steep hills and mountains. While it may move slowly, speed isn’t the consideration when it comes to getting a houses modules to the site location.

Translift – A Translift is a machine that is basically a steel I-beam on tracks. This machine can be maneuvered under a modular carrier to lift it and then move the carriers from side to side. While it doesn’t have the range of motion that a Jade has, it is faster to get into position when all that is needed is a little help to get around a tight turn. It can also be a big help onsite with installation of the home module on the foundation in some installations.

Translift – A Translift is a machine that is basically a steel I-beam on tracks. This machine can be maneuvered under a modular carrier to lift it and then move the carriers from side to side. While it doesn’t have the range of motion that a Jade has, it is faster to get into position when all that is needed is a little help to get around a tight turn. It can also be a big help onsite with installation of the home module on the foundation in some installations.

Jade – A Jade is a piece of equipment that attaches to the rear of the frame of the carrier used to transport a module to a home site. The wheels of the Jade are remote controlled and the piece of equipment can also lift the carrier vertically. This machine allows an operator to have an extreme range of motion when navigating bends, curves, and turns with long modules in tight areas.

Jade – A Jade is a piece of equipment that attaches to the rear of the frame of the carrier used to transport a module to a home site. The wheels of the Jade are remote controlled and the piece of equipment can also lift the carrier vertically. This machine allows an operator to have an extreme range of motion when navigating bends, curves, and turns with long modules in tight areas.

Modular Means Designed for Delivery

A modular home is really a home that was built using modular construction. The house plan is divided into modules that can be built using the advantages of offsite construction. The modules are then delivered and assembled onsite. The sophistication and complexity of design that a modular home factory can build has grown substantially over the years. Generally, factories with the most advanced technology that can produce modular homes with assembly line techniques are located in the eastern U.S. While many factories exist that can produce truly unique homes through the rest of the country, they seem to be the most prevalent in the Mid-Atlantic States and in the Northeast.

Styles such as chalets with high vaulted ceilings and homes with large, open floor plans can be built in a factory. This is accomplished using steel that is integrated into the construction of the home or with engineered lumber which is integrated to meet the needs of the home design. Home designs are built in a factory in such as way that home modules can be installed on site creating a home that meets the needs of today’s home buyer.

Make it Modular

The post How We Get Home Modules to Difficult Home Sites appeared first on Impresa Modular.