2020: The Inflection Point Year for Modular Construction

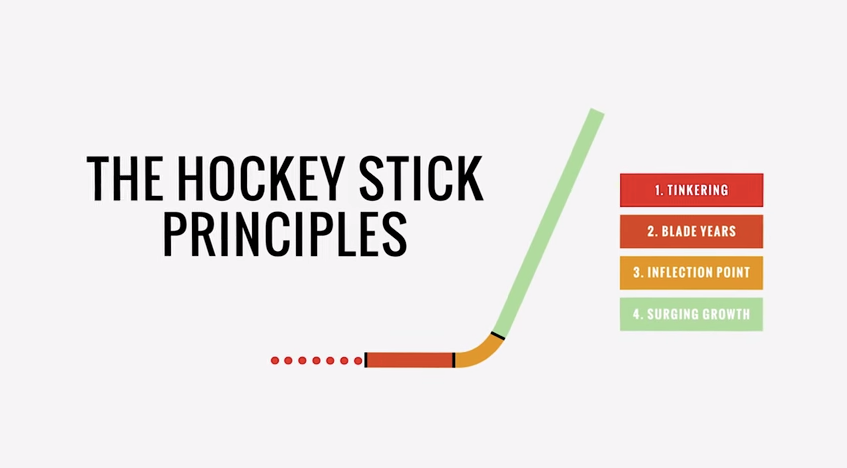

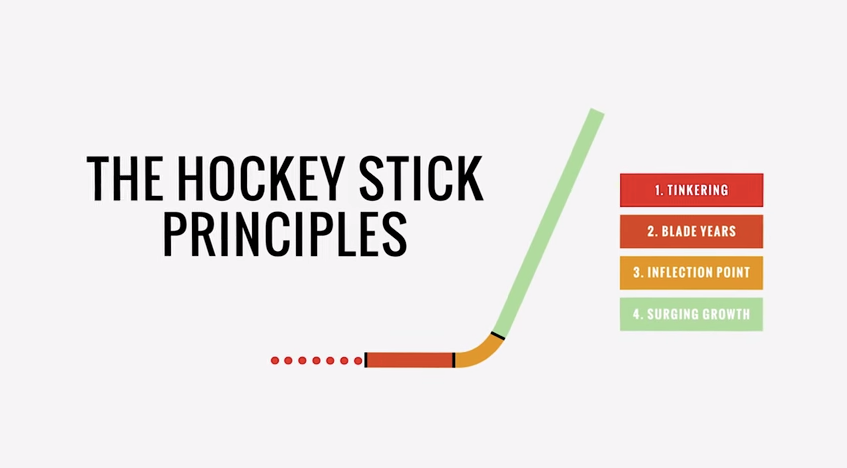

HEADER PICTURE: The Hockey Stick Principles, Flatiron Books

Residential construction in the U.S. has changed. While getting skilled and trained labor in many industries is hard, getting it in the construction industry has gotten more difficult than ever with no end in sight. Material prices continue to rise. Taxes and tariffs have added to the cost of construction. Updates to building codes are adding requirements which are adding even more mandatory costs to every home. And… we have a housing shortage in the U.S. We have reached the inflection point for modular construction. We are breaking free of the shackles of traditional construction. Home buyers and home builders are adopting modular construction as the best way to meet the quality, value, comfort, and safety needs they demand in today’s home. Modular construction is now ready to take the upward turn to surging growth as the modern way to build.

Hockey Stick Principles

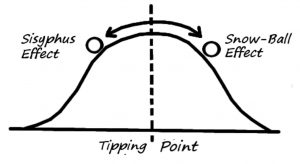

Over the years, the growth of an industry can be described as a hockey stick. This hockey stick growth pattern is divided into 4 parts:

- Tinkering – The industry is being established and manufacturers are committed to finding better ways to make the product and navigate the process improvement maze.

- Blade Years – During this period the industry has a solid basis. There are many producers and the industry is firmly established. It markets its a superior product; however, growth is hit and miss as the industry works to find its way into the mainstream.

- Inflection Point – This is the period of initial excitement as the mainstream delivery channels and consumers discover this “new” industry and rapidly accept and begin adopting the new product and processes.

Surging Growth – When the number of adoptions reaches a critical mass or “The Tipping Point”, accelerated growth begins and the industry flourishes as rapid adoption by everyone occurs.

Surging Growth – When the number of adoptions reaches a critical mass or “The Tipping Point”, accelerated growth begins and the industry flourishes as rapid adoption by everyone occurs.

Offsite modular construction is no different. While many have acknowledged for years the superior value, quality, and speed of delivery for homes built with modular construction, the industry has remained in the Blade Phase as industry growth was stifled by a recession each time it was racing to the Inflection Point.

How it Worked for Japanese Car Makers in the U.S. Auto Industry: 1970 versus 1990

In 1950 the U.S. auto industry produced three-fourths of the world’s automobiles. Going into 1970 the big three automakers were building bigger cars and developing lots of options. And then there were the Japanese cars. In the 1970’s they were thought about as cheap, flimsy, low quality automobiles… but the consumer was buying them. They didn’t have many options, they were boxy with very little design details and they weren’t very big. But each year, the Japanese car companies were selling more. Every year they got better and better.

They got better gas mileage and their designs continuously improved. Because they were small, buyers were concerned about safety. With their smaller size, safety had to be engineered into each car. The Japanese car makers were chipping away at the Big Three Automakers market. The oil embargo and the subsequent rise in gas prices made the Japanese cars an even better, more cost effective option for the American car buyer.

It took time but over a period of about 20 years what was the inferior, cheap product in 1970 (Tinkering) became the industry leader by 1990 (Surging Growth). Japanese car companies led in design, safety, durability, and manufacturing efficiency. That last item was critical in Japan’s success. By building a car more efficiently it could deliver quality, well designed and safe cars at a value that the U.S. automakers just couldn’t compete with. It was the process that created a better product.

Stage 3: Inflection Point – The Case for Modular

So what has changed? This time it’s the perfect storm of events. The home building industry is struggling to build homes the traditional way. The inefficiencies of the older methods are finally catching up with the industry. With all of the technology available today, the productivity has remained flat for the last 20 years. This, while productivity in the manufacturing sector has nearly doubled! Add to this the lack of skilled workers in construction and desperate lack of available affordable housing in the U.S. and you can see why this is modular’s moment.

Marriott, one of the best known hospitality brands in America, has taken the plunge. Faced with the longer construction time frames, quality concerns, and rising prices had to evaluate it options. The traditional way of building just wasn’t working in the current environment. They have reviewed the process and the method and have decided to go full speed ahead with their modular construction initiative and build 50 new modular hotels this year.

Modular construction allows home construction to be turned into a manufacturing process. Just like with the Japanese, the secret was in the process. By turning the construction of homes into a manufacturing process, quality can be enhanced. It is much easier to hire labor that is working indoors with steady, non-weather driven employment and that comes to the same workplace each day. Building in a factory also allows unskilled labor to be trained and supervised in an environment that readily lends itself to continuous and managed improvement.

And the economy continues to boom. The predicted recession has not happened. What has stopped previous runs for Modular to the Inflection Point hasn’t occurred. Interest rates continue to be at historic lows and home buyers want homes, affordable homes. Modular construction has finally made it to the Inflection Point!

The Race to Stage 4: Surging Growth

Marriott and many other hotel chains have found the value in modular. Good, custom home builders are discovering that modular homes can not only offer great value but also a great design. The design was one of the things that held back Japanese car sales growth in the beginning. They were small and all looked the same. They just didn’t compete with the larger, more stylish U.S. made cars. By 1990 they had award winning designs along with better quality, better performance, and better durability.

Home performance is another area of growing importance. Not only are building codes requiring more from the homes we live in, but customer are also demanding homes that are better for the environment and better for their budget. The tighter tolerances, the quality construction, and a better insulated home means energy bills are lower for most home owners that build with modular. All of this comes at a value that can only be offered because of the efficiencies that come from building in a factory.

The Future is Modular

The future is in off-site construction. Commercial construction has embraced it for years. In fact, modular construction for commercial has turned the bend is at the beginning of Stage 4: Surging Growth. Hotels, office buildings, medical facilities, assisted living homes, etc. All of these projects are being completed with modular construction. Most custom builders have struggled for years to embrace the rise of modular construction. However, the internet has become a tremendous resource for home buyers building a new home. Today’s home buyers are doing the research. They are learning about the advantages that modular construction provides. They are learning about the difficulties the construction industry is having with labor and the resulting issues it is causing in new home building. Today’s home buyers want more. Today’s home builders are realizing they have to make the change. The culmination of these two events has placed modular construction squarely at the inflection point. Modular is poised to take its place as the dominant way to build all new homes!

The future is in off-site construction. Commercial construction has embraced it for years. In fact, modular construction for commercial has turned the bend is at the beginning of Stage 4: Surging Growth. Hotels, office buildings, medical facilities, assisted living homes, etc. All of these projects are being completed with modular construction. Most custom builders have struggled for years to embrace the rise of modular construction. However, the internet has become a tremendous resource for home buyers building a new home. Today’s home buyers are doing the research. They are learning about the advantages that modular construction provides. They are learning about the difficulties the construction industry is having with labor and the resulting issues it is causing in new home building. Today’s home buyers want more. Today’s home builders are realizing they have to make the change. The culmination of these two events has placed modular construction squarely at the inflection point. Modular is poised to take its place as the dominant way to build all new homes!

The post 2020: The Inflection Point Year for Modular Construction appeared first on Impresa Modular.

Surging Growth – When the number of adoptions reaches a critical mass or “The Tipping Point”, accelerated growth begins and the industry flourishes as rapid adoption by everyone occurs.

Surging Growth – When the number of adoptions reaches a critical mass or “The Tipping Point”, accelerated growth begins and the industry flourishes as rapid adoption by everyone occurs.