Log Homes vs. Modular Log Homes: Insulation 101

A.K.A. WHAT THEY DON’T TELL YOU AT THE LOG HOME SHOW.

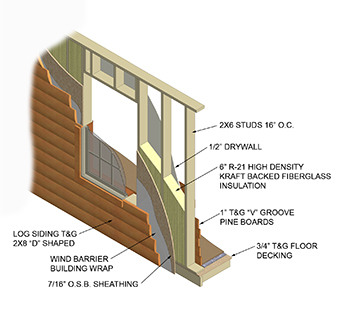

Several weeks ago I attended a Log and Timber Show in Pennsylvania. I always enjoy seeing new designs, talking with architects, and seeing what new products and techniques are being offered to treat and maintain homes constructed entirely of wood. One of the things I saw for the first time was a display by one log home company that showed the options for the construction of their log walls. I took the opportunity to get a couple of pictures. This display is great for illustrating the striking differences between insulation for modular log homes and traditional log homes.

First the Background

When building a home to be energy efficient you will hear lots of terms that can sound very complicated, even intimidating. They include things like thermal envelope, R-value, U-value, thermal bridging, thermal breaks and the list goes on and on. Here is a brief explanation of some key terms.

- Thermal Envelope – It is the configuration of the enclosure that holds warm or cool air inside a structure. It is the collection of walls, windows, doors, floors and ceilings that combined, make of a structure of the building.

- R-Value – It is the capacity of an insulating material to resist heat flow. The larger the R-value number is, the better the insulating power.

- U-Value – It is a rating of how much heat energy is lost or gained. It is the opposite of inverse of R-value so the lower the number, the better the rating. It is typically seen on windows and doors.

- Thermal Bridging – The term bridging describes the area of an object which has a significantly higher heat transfer than the surrounding materials resulting in an overall reduction in thermal insulation of a building. For example, the locations of studs in a 2×6 or 2×4 wall system.

- Thermal Break – When building a wall, it is a barrier or an element of low thermal conductivity placed in the wall to reduce or prevent the flow of thermal energy between conductive materials.

With the stick framed construction used by modular log homes, the actual 2×4 or 2×6 stud has the lowest R-value in the thermal envelope. Because the insulation in the wall is typically rated at R-21, thermal bridging takes place at the stud because the framing stud is only rated at an R-4 or R-6. The way to reduce thermal bridging is to reduce the required number of studs in a wall. Wood just inherently has a low R-value. While it depends on several factors, wood has an R-value ranging from .71 to 1.4 per inch of thickness (yes, you are reading that correctly).

Related: 10 POINTERS TO BOOST YOUR CREDIT – QUALIFYING FOR A CONSTRUCTION LOAN

Insulating with Wood

Wood has natural beauty and offers lots of strength. However, building code uses R-value to measure energy efficiency and this is where wood just doesn’t measure up. Energy efficiency is playing a greater role in today’s updated building codes and is becoming even more important to today’s homebuyer. Log home buyers are looking for a feeling… a lifestyle that only the look of natural wood can give them.

R9 – R16 Log Wall

That is why I found the display at the Log Show so interesting. To meet current building codes and provide higher energy efficiency, the log home company has devised several ways to increase the R-value of their log walls. While there are several types of log styles to choose from, this display used an 8” D-log style. If we assume an average R-value of about 1.1 per inch, that means we have an R-value of approximately R-9. That doesn’t meet current building code.

To meet building code, the first option is to add furrowing strips and some foam board insulation to get to an R-16. Over the years, log homes have gotten expensive. In fact, most log homes cost 25-40% more than a comparable framed home. In most cases, a log home doesn’t appraise for what it costs to build. Now, to meet building code, this log company has to add the additional cost (of both material and labor) to cover the beautiful logs that you paid extra for with foam board and then apply 1×8 tongue and groove boards to make it look like you are viewing the original wood logs on the interior of the home. And, after all of this, the wall still doesn’t reach the same R-value, or have the same stability, that a stick framed modular home can provide as standard.

R23 Log Wall

The log company even offers an upgrade option to improve the exterior wall insulation. The solution is to install a thicker foam board with an even higher R-value rating. This comes at additional expense and extra effort to install. Notice the top of the picture of the R-23 wall. See how the roof/ceiling meets the log wall. This is a point that is critical to maintaining the thermal envelope. It doesn’t matter how much insulation you have if all of your warm interior air escapes through dozens of cracks and gaps to the outdoors.

The designs for log homes today are stunning. Architects and designers have been creating amazing large, open floor plans with vaulted ceilings, prow fronts, lofts, and unique features. While that has created beautiful homes it has also created a long list of field construction issues. Natural wood shrinks and expands with humidity and temperature changes. When wood logs, boards, and timbers of multiple thicknesses and angles is assembled, the thermal envelope becomes dependent on a host of methods (caulks, screws, etc.) to maintain its integrity. While log homes are beautiful, they now cost more to insulate, are hard to seal, and expensive to maintain.

Get the Same Look and Feel

Modular log homes are essentially a stick framed home but with log siding and 1×8 tongue and groove boards. Log companies have created several styles of log siding to emulate dimensional logs for home buyers that don’t want, or can’t afford, real logs but refuse to give up the dream of living in the natural beauty of a log home.

Because modular homes are very energy efficient and cost effective to begin with, many homebuyers find that using modular construction is the perfect way to get the log home of their dreams. There are several advantages to modular log homes:

- Modular Log Homes build on the already energy efficient modular home structure.

Cut Away Sections – Log Siding

- Because the home is stick built, the walls don’t shrink and expand with changes in temperature and humidity.

- The value of modular construction becomes even more apparent, costing up to 25-40% less than a comparable conventional log home.

- A modular log home is virtually identical in style, look, and feel to its true log home counterpart.

- Offers more available interior design options since each room can reflect the log home style as little or as much as you desire.

In conjunction with R-21 high density fiberglass insulation, the remainder of the interior and exterior wall materials means that the “average” modular log home will have an R-value rating of about R-25. From there, other modern insulation alternatives can be applied. For example, spray foam insulation/fiberglass batt and exterior foam board could easily increase the walls rating to R-49. Modular construction provides the option to create a super energy efficient home that is virtually imperceptible from a traditional log home.

Modular log homes give you the look and feel you want, the structural stability of a stick built home, the cost savings and comfort of energy efficiency, and for far less than than you might expect to pay for a traditional log home. In a future post I’ll talk about the structural and maintenance advantages that make this approach to the log home lifestyle even more enticing!

See my previous post: Modular Homes: The Ultimate Log Home Kit.

The post Log Homes vs. Modular Log Homes: Insulation 101 appeared first on Impresa Modular.